Product

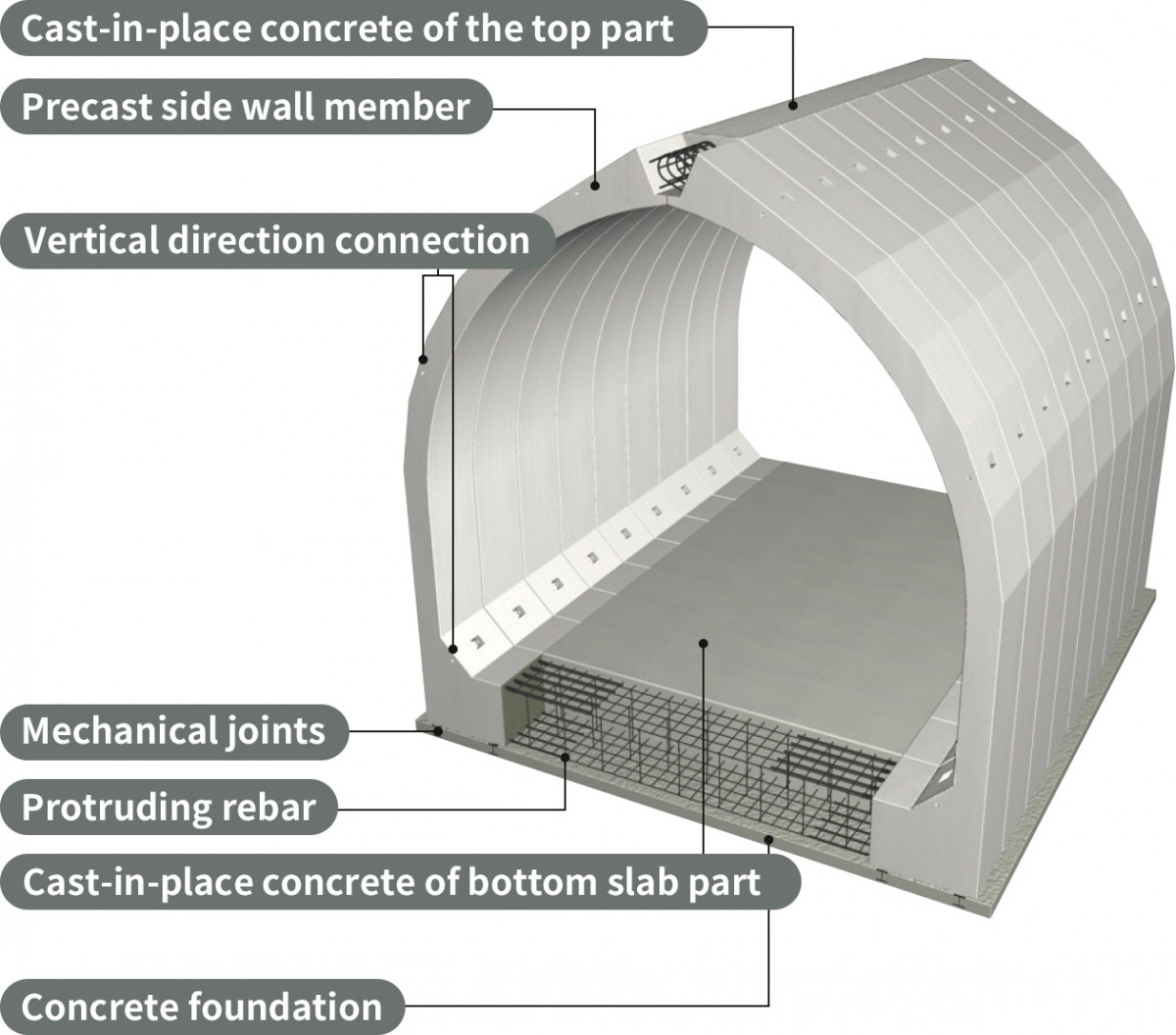

Loop Arch

Standard width of inner space 4.0m - 8.0m of the arch culvert

It is possible to shortening the construction time and minimizing the laborsaving by a construction method to build the arch culvert of large cross section employed with the cast-in-place concrete and precast members that have been divided into two part.

Features

Design condition

| Inner space width | 4000mm~8000mm |

|---|---|

| The overburden and thickness | Up to 15m |

| Above the mounting load(transverse direction) | It corresponds to 25 tons |

Corresponding high overburden soil

Because of arch shape and resistant to high overburden soil, it enables an economic cross-sectional design as compared to the box shape.

High workability

It encourages construction time and improves workability in which arch section is composed of two split symmetrical part compared with the conventional three-part arch structure. Also, because the product can stand-alone without support, it is a possible to construct using one crane.

Connection part is rigidly connected

Connecting part has adopted a rigidly connected by the loop joints and mechanical joints and cast-in-place concrete.

Special work is unnecessary

Hence the loop joints adopted in the connection method of the top part and the vertical direction also connected by the steel bar connection,special work such as a conventional PC tension engineering is not required.

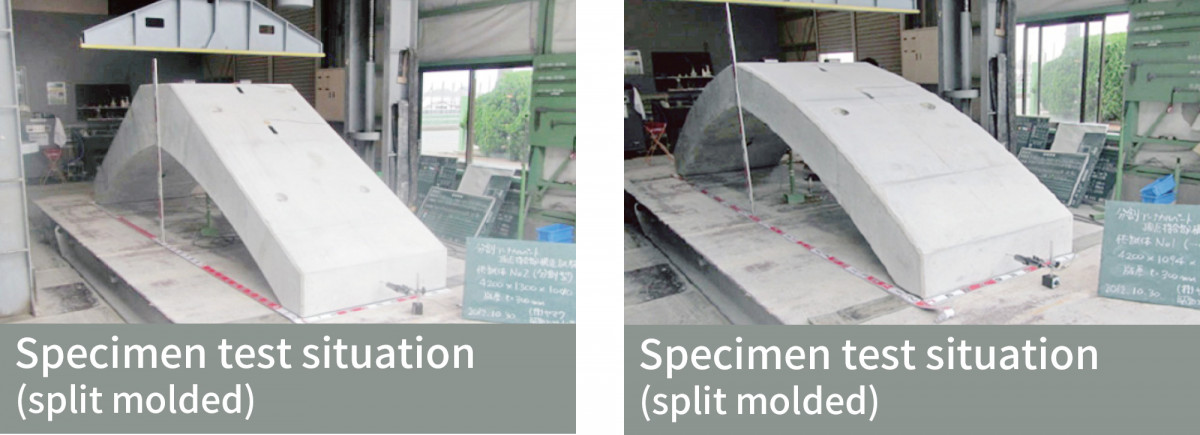

Performance test (Collaboration with Kyushu University)

To verify the loading test of the structural performance of the loop arch and to confirm the workability, assembly experiment was carried out.